Enhance Taste. Preserve Freshness.

Pentair’s smart CO₂ dosing and blending systems ensure full and controlled dissolution of CO₂ or other supplements, thanks to integrated measurement and correction technology.

BENEFITS

- Prevents CO2 losses.

- Easy installation & low maintenance.

- Accurate, reliable & automated (optional) process control.

- Enhances the taste & freshness of your beverage.

- Cost-saving operation.

- Scalable for small to large breweries.

Brewery Size, Different Needs

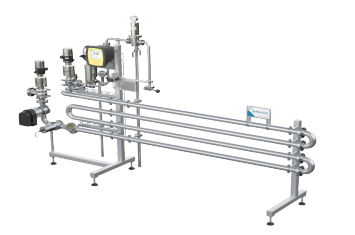

For micro or craft breweries, a simple in-line carbonation unit is often the ideal choice. These systems are:

- Easy to install.

- Low maintenance.

- Designed for maximum CO₂ saturation.

Larger breweries, on the other hand, typically require more advanced solutions. They benefit from:

- Greater control and automation of CO₂ dissolution.

- Integrated blending and carbonation in a single unit.

- Space-saving design and improved process efficiency.

Our Carbonation & Blending Systems

CARBO CONTROLLER

The Carbo Controller (CCR) is Pentair’s automated solution for precise CO₂ injection. It works by introducing CO₂ at the inlet of a dissolution tube, where it is finely dispersed and dissolved using static mixers tailored to your process.

An in-line CO₂ meter (Haffmans AuCoMet-i) continuously measures CO₂ levels and adjusts dosing in real time. The AuCoMet-i communicates directly with Pentair’s CO₂ dosing block via embedded software, ensuring consistent carbonation. Optional oxygen measurement is also available to help monitor and maintain product quality.

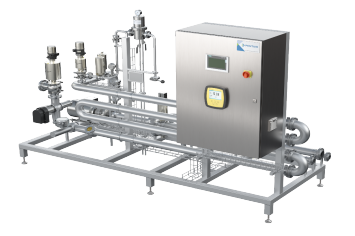

CARBO BLENDER

The Carbo Blender is Pentair’s most sophisticated solution for both blending and carbonation. It precisely controls the water-to-beer ratio, with automatic correction of original gravity or alcohol content via PLC control—ensuring a highly accurate and efficient blending process.

Once blended, CO₂ is injected at the inlet of a dissolution tube, where it’s finely dispersed and dissolved using static mixers.

For breweries using High Gravity Brewing, the Carbo Blender integrates seamlessly with Pentair’s Beer Membrane Filtration and Water Deaeration systems—giving you a complete, high-output solution.

Related products

wds

- Main

-

Achieve exceptionally low levels of dissolved oxygen in deaerated water with our WDS system.

Related Case study

Automating Inline Carbonation

Founders Brewing Co., United States of America

A/S Bryggeriet Vestfyen - Denmark

"INLINE" FOR EFFICIENCY

SUMMIT BREWING COMPANY - MINNESOTA, USA

THE BEAUTY OF BREWING

Trillium Brewing Company - USA

INCREASED ACCURACY

- Hero1

- Hero2

- Hero3

- Hero4