PRODUCT INFORMATION

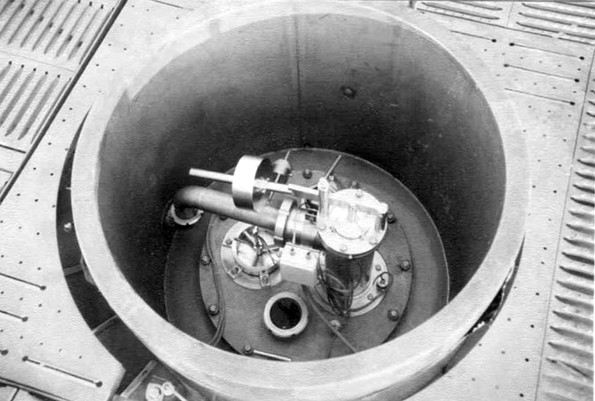

Pentair Südmo Safety Valves limit the pressure in pressurized units like steam vessels, chemical reactors or storage tanks. The pressure vessel is secured via a vacuum valve against underpressure and via a safety valve against over pressure.

BENEFITS

Südmo safety valves are divided according their working mode into:

- weight loaded safety valves

- spring loaded safety valves

According to the media for which the valves are approved:

- gases/steams

- fluids

-

FUNCTIONAL DESCRIPTION

-

Overpressure protection

In the event of gas venting being blocked or closed off, the maximum strength of the tank can be exceeded under various operating conditions such as filling, overfilling, fermentation, or chemical reactions, which can lead to an explosion. A spring-loaded safety valve, manufactured and verified in accordance with pressure equipment guidelines, is part of the fitting and protects against overpressure.Vacuum protection

Draining, leaking, chemical reactions, content cooling, or vapor condensation can cause the tank pressure to drop below the minimum if the gas supply or ventilation is blocked or closed off, which can lead to implosion. A spring-loaded or weight-loaded vacuum valve is part of the fitting and protects against vacuum.

-

FIELDS OF APPLICATION

-

Pentair's Südmo safety valves are used across the applications in brewing, food, beverage, winery, pharmaceutical and cosmetic industries.

DOWNLOADS

| Title | Download PDF | |

| Catalog | Südmo Components | Contact Us |

| Technical documentation | Looking for operating instructions, installation manual, spare part list etc.? | Please, send us your request |

RELATED PRODUCTS

SÜDMO TANK TOP SYSTEMS - TANKTOP

Proven simple and reliable compact system that allows the addition and removal of gases and CIP cleaning fluid using one process connection.

SÜDMO HYGIENIC BUTTERFLY VALVES K 580 / K 660 / K 680

Ideal solution for shut-off function across all segments of the hygienic process industry.

Südmo Non-Return Valves are designed to prevent blackflow of media in the process plant.

SÜDMO SINGLE SEAT VALVES SVP SELECT

The best basis for efficient and safe production processes due to the wide variety of options provided by our modular system, ease of maintenance, cleanability, and the options for the valves to meet the latest hygiene and aseptic requirements.