Pasteurization monitoring

The distinct taste and superior quality – that’s what consumers aim for when buying your product. The constant need for efficiency, variety, and flexibility in production puts additional pressure on food and beverage processors.

Pentair Haffmans Pasteurization Monitoring puts you at ease when it comes to product quality and optimizing the performance of your pasteurization line as your key quality parameter - so you can focus on that distinct taste.

The Haffmans Pasteurization Monitor is available to measure the performance of your pasteurizer.

So start now by monitoring your Pasteurization lines to improve your product quality and shelf life.

Benefits

- Perfect process control

- Maximum flavor retention of the product

- Extra shelf life

- Reduction of product loss

- Optimized energy consumption

Why it is it important to monitor your pasteurizer?

Pasteurization reduces the number of microorganisms in beer and beverages which increases the product’s shelf life. To maintain the quality of the product with regard to taste, smell, brightness, and color, pasteurization should be a gentle heat treatment. The most commonly used method of pasteurization makes use of a tunnel pasteurizer, through which containers, such as glass bottles and cans, travel while being sprayed with hot water.

But how do you safeguard the performance of the tunnel pasteurizer?

-

PASTEURIZATION MONITORING POSSIBILITIES

-

CALCULATING PASTEURIZATION UNITS (PU)

Haffmans delivers equipment for reliable monitoring of tunnel pasteurizers in breweries and the soft drink industry. Sufficient heat treatment of bottles or cans determined by multiple temperature probes during the pasteurization process is ensured by reaching the minimum required PU’s (at the coldest spot). Setting the optimal automated PU values avoids over-pasteurization (loss of aroma and taste) and reduces energy consumption.SPRAY MONITORING

Monitoring the spray temperature is used to view the temperature of the individual temperature zones and to identify the location of any bent or clogged spray heads. As the bed is in constant motion a sample time of at least 10 seconds is required to determine an accurate location for a damaged head.Delta T (ΔT) can also be measured i.e. the difference between the temperature inside the package and outside. This is of interest when pasteurizing bottles, as too great a Delta T during the heating or cooling cycles would likely lead to breakages.

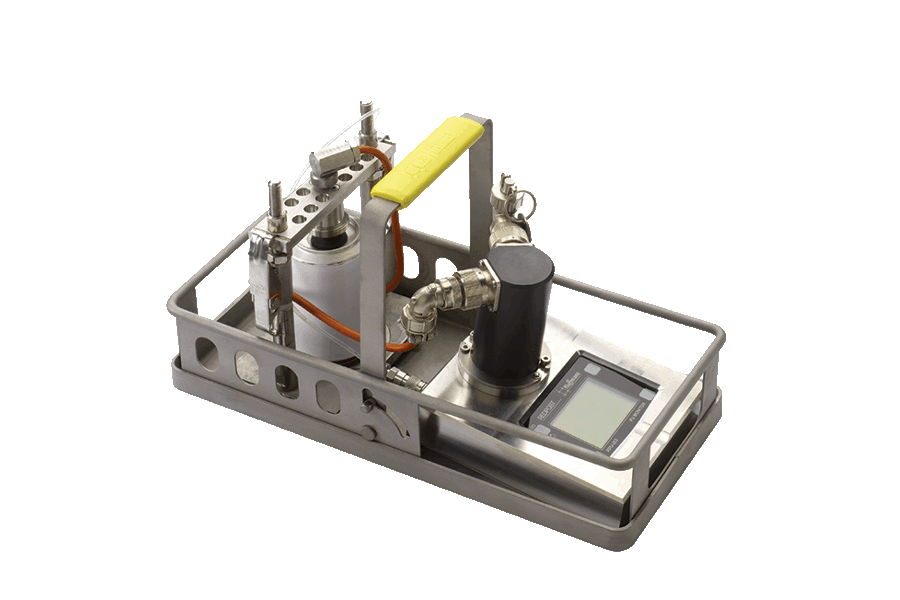

The Haffmans RPU-352 and Haffmans RPU-353 have two temperature channels to allow measurement of product and spray temperatures.

PRESSURE MONITORING

During pasteurization the pressure in the container increases. This is partly due to the rise in temperature acting on the CO2 gas already in the headspace and partly due to the vibration, which encourages CO2 to be released from supersaturated solution in the product. The practice of using nitrogen for purging containers and for fobbing produces a mixture of gases in the headspace that may increase the pressure rise. Over the years there has been a trend towards ever thinner-walled can packages, as well as reduced head space volumes. Both these factors make problems of over-pressure more significant, with peaking or breakages the result. When pasteurizing cans with internal pressure reservoirs or 'widgets' the internal pressure also needs to be monitored closely.A Pasteurization Monitor with a pressure measurement channel can assist with this; it is attached to the bottle or can and is designed to make as little change to the headspace of the package as possible so as not to affect the results. The graph of pressure can then be examined to observe maximum pressure along with any obvious spikes.

The Haffmans RPU-353 has a pressure measurement channel as well as two channels for product and spray temperature.

EXIT TEMPERATURE

The temperature that the bottles or cans leave the tunnel pasteurizer can be very important. If the product leaves at too high a temperature the flavor of the product may be affected. Because of this, some package specifications state a required product exit temperature. As the PU Monitor recording run may not be stopped immediately after the product leaves the tunnel, it may be difficult to determine the exit temperature by looking at the temperature graph alone. To solve this problem all Haffmans Pasteurization Monitors are fitted with a sensor that determines when the PU monitor leaves the pasteurizer and the temperature of the product is recorded at this point.LETHAL PUs (LPUs)

Lethal PUs are used by some brewers and bottlers as an extension to the PU system. Rather than having just one PU Cutoff value, under this system, there are Total-PU values and Lethal-PU values. The Total-PU cutoff would be set at say 55 °C and the Lethal-PU cutoff at 65 °C the PU Monitor would then give the two PU results.The common reason for using this methodology is as a backup to ensure that the product has completed the expected temperature curve. With some resilient microorganisms, the temperature curve is important and the product must be above the Lethal Cutoff for a certain time to ensure stability.

Lethal PU calculation is available in Redpost Redlink software.

DOWNLOADS

| Title | Download PDF | |

| Product Overview Brochure | Haffmans Quality Control Equipment | DOWNLOAD |

Related products

HAFFMANS PASTEURIZATION MONITOR - RPU

The Haffmans pasteurization monitor provides immediate insight of your tunnel pasteurizer’s performance.