CO2 Recovery for Craft Breweries

CO₂mpactBrew is Pentair’s compact CO₂ recovery solution designed for smaller, craft-sized breweries. It ensures a continuous supply of beverage-grade CO₂, helping you cut costs, reduce emissions, and operate sustainably.

Benefits

- High-Purity CO₂: Liquid CO₂ purity ≥99.998% v/v, O₂ ≤5 ppm v/v, meeting ISBT and EIGA standards.

- Compact Footprint: Pre-mounted on a single 40 ft skid for easy installation and relocation.

- Plug-and-Play Design: Delivered pre-wired, pre-piped, and ready to run, fast commissioning guaranteed.

- Safe & Refrigerant-Free: Uses brewery glycol for liquefaction, no Freon or ammonia required.

- Scalable Capacity: Same footprint from day one, even as your production grows.

- Optional Containerized Solution: Ideal for breweries with limited indoor space.

- High Recovery Efficiency: Even at low inlet CO₂ purity (≥95% v/v), ensuring maximum yield.

- Robust & Reliable: Built for 24/7 operation with uptime ≥95%.

-

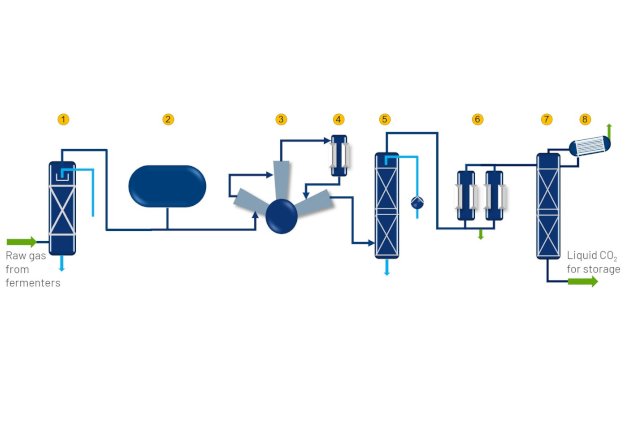

Functional Description

-

- Raw foam-free fermentation gas is fed to the CO2mpactBrew system, where water-soluble contaminants such as ethanol are scrubbed in the low-pressure gas washer (1) prior to it being buffered in the balloon (2).

- A dry-running 3-stage CO2 compressor unit (3) increases the gas pressure to 48barg (696 psig), removing condensate in the process.

- H2S is filtered after the 2nd stage (4). The remainder of the impurities and water is then removed in the high-pressure gas washer (5), respectively online drier (6).

- Regeneration of the off-line drier is automatic, utilizing heating elements and dry CO2 purge gas. CO2 liquefaction takes place in the glycol-cooled condenser (8), and O2 is removed in the stripper (7).

- The flash gas is led back to the 2nd stage of the CO2 compressor, whilst the purified liquid CO2 end product is fed at 15 barg (218 psig) to the onsite storage tank.

-

Options

-

- Ventilated 40 ft high cube container

- Foam separator

- Liquid CO2 storage tank

- Ambient air heated CO2 vaporizer

- Cylinder filling unit

- Road tanker pump

- Quality control equipment

- Installation and commissioning services

- Original spare parts

- After-sales services

Related products

HAFFMANS CO2 RECOVERY PLANT - ECO2BREW

ECO2Brew is unique in its design to recover CO2 from fermentation processes at larger 24/7 operating breweries, over 2,000,000 hl/yr.

HAFFMANS CO2 RECOVERY - SYSTEM ENERGY SCAN

Scan your CO2 Recovery Systems with Haffmans and get detailed information on energy consumption, performance and quality.

HAFFMANS CO2 RECOVERY PLANT - CRU

Robust and reliable CO2 recovery solution for a wide variety of brewery needs ranging from 300,000 to beyond 5,000,000 hl/yr.

The analysis of both commercial and recovered gas - an excellent tool to check the performance of the CO2 Recovery Plant.