PRODUCT INFORMATION

Pentair’s BeerStab is the most straightforward, user friendly beer stabilization system, ensuring what you need: stable beer. Beer loss is reduced to a minimum and the same applies to the consumption of water, chemicals, and utilities.

THE MOST STRAIGHTFORWARD BEER STABILIZATION

Beer consumers like to enjoy a bright beer. Hence, brewers seek to brew a beer, which is bright on the shelves and stays that way for a long time. To be able to achieve that, you need a reliable beer stabilization.

Pentair’s BeerStab is the most straightforward, user friendly beer stabilization system, ensuring what you need: stable beer. Beer loss is reduced to a minimum and the same applies to the consumption of water, chemicals, and utilities. With the lowest footprint possible it can easily be retrofitted and integrated into the smallest operation.

Operation is robust and simple while keeping costs low: a small system volume, no pumping around of PVPP, and the PVP is fixed. As a bonus, you have a straightforward regeneration of the PVP with plain caustic and ambient temperature levels. No CO2 is needed. Most importantly, the removal of polyphenols is guaranteed up to the level you need.

Small batches, brand changes, and variable flows are easy to handle by Pentair BeerStab, reducing disruptions in your production process.

TECHNOLOGY & PROJECT MANAGEMENT

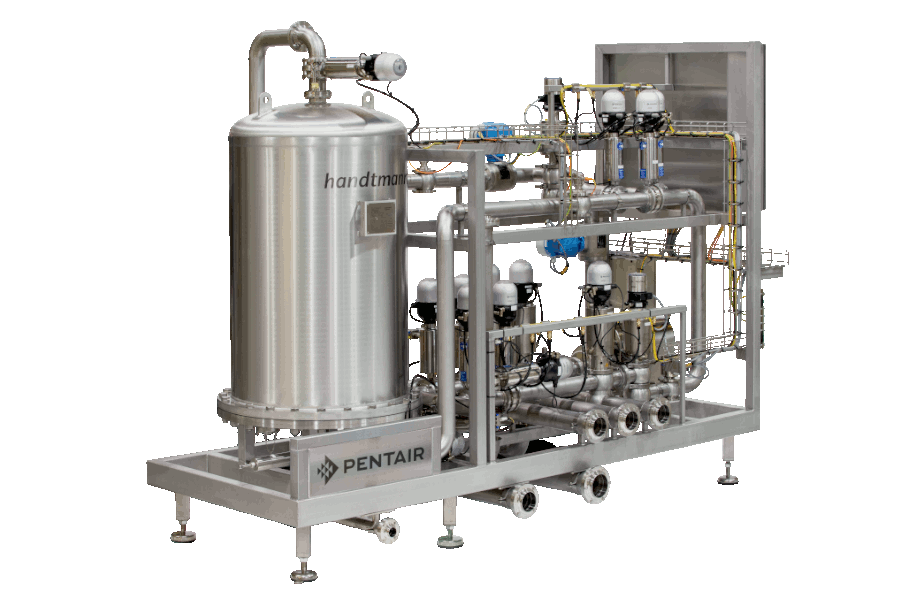

BeerStab uses the Proven Technology of Handtmann, with cross-linked PVP on a carrier material called Agarose, fixed in a radial flown column. This, paired with Pentair’s own engineering and project expertise as well as proven beer membrane technology, assures you that Pentair truly offers One-Stop Shopping: one Capital Expenditure, one Operational Expenditure, one list of KPI’s - all in one contract.

BENEFITS

- Excellent physically-chemically stable beer

- Low chemical and water consumption due to small system volume

- Very low beer loss, 0.01 % or less

- Favorable TCO

- Simple in process, maintenance, and handling

-

PROCESS DESCRIPTION

-

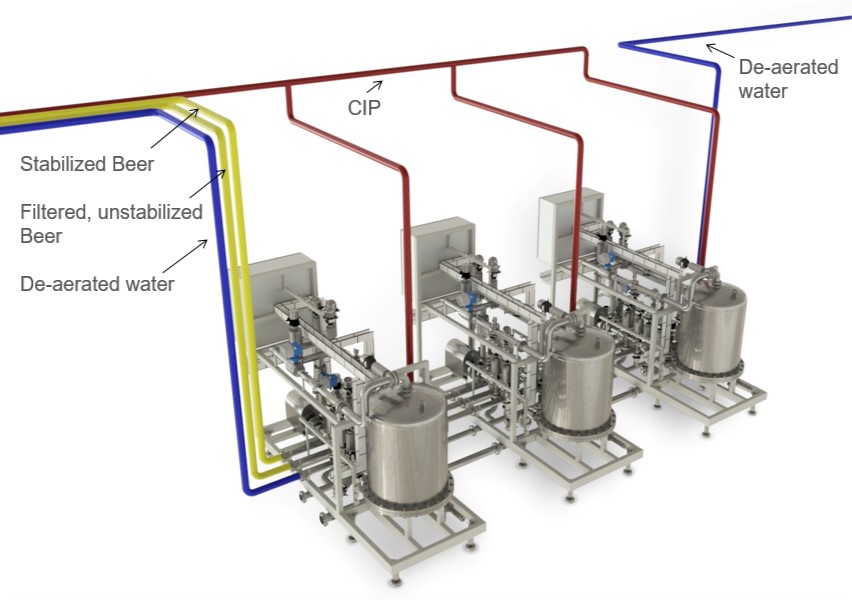

Example of a Continuous BeerStab 400 hl/h

Three alternating units, each unit has a Radial Flow Column filled with fixed PVP for removal of polyphenols. Filtered, unstabilized beer flows to one of the adsorption units. One part flows through the adsorption column, another part flows as a by-pass and is mixed with the flow out of the adsorption column. At the beginning of the run cycle, the by-pass is on its largest. During the run, the by-pass is reduced and the flow through the adsorption column is increased. The total flow is at a constant level. For each beer type/batch, the amount of polyphenols to be removed is set. When the by-pass is zero, the stabilization process stops and the adsorption column is regenerated with cold caustic. Typically, once per week, sterilization takes place with hot water.The PVP-Agarose is compliant with:

- German Rheinheitsgebot

- FDA 21 CFR 173.25.c

- EC Food Contact Material 1935/2004

-

SCOPE OF SUPPLY

-

- One, up to four adsorption units, depending on requested capacity

- Batch or continuous operation

- Designated CIP unit - no tank, in-line cleaning

- Fully automated

- Fully integrated with BMF

- Installation possible in existing BMF

- Service Packages: 24/7 Helpdesk, Monitoring, Reporting

- Turnkey Project

- One, up to four adsorption units, depending on requested capacity

DOWNLOADS

| TITLE | Download PDF | |

| Product leaflet | Beer Stabilization System - BeerStab | Download |

| Technical documentation | Looking for operating instructions, installation manual, spare part list etc.? | Please, send us your request |

Related Products

Beer Membrane Filtration System for large breweries that produce at a capacity between 200-900 hl/hr.

Turnkey filtration solution for breweries with capacity 7,000–22,000 hl/d.

Beer Membrane Filtration System for small and craft breweries that produce at a capacity between 30-80 hl/hr.