PRODUCT INFORMATION

Pentair offers complete and fully certified header tank systems specifically engineered for dust collector filter cleaning. We introduced the Full Immersion system with optimized flow rate for the best cleaning results in the market. All our pressure vessels are guaranteed to meet international regulations.

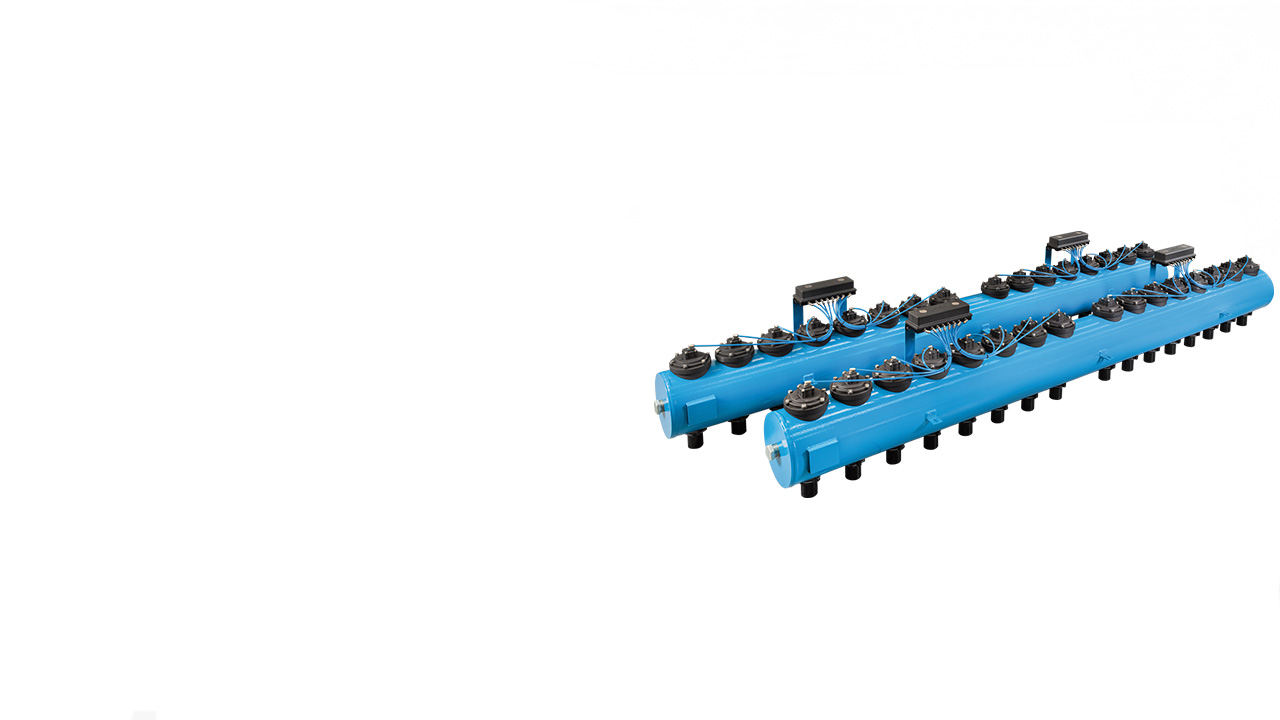

Engineered Header Tank Solutions: Full Immersion System Design

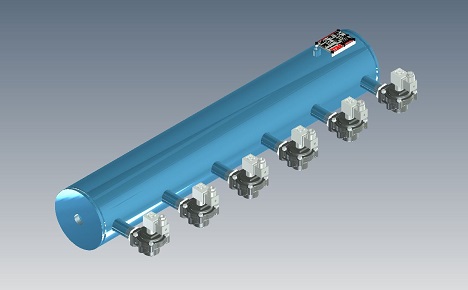

Engineered Header Tank Solutions: Non Immersion System Design

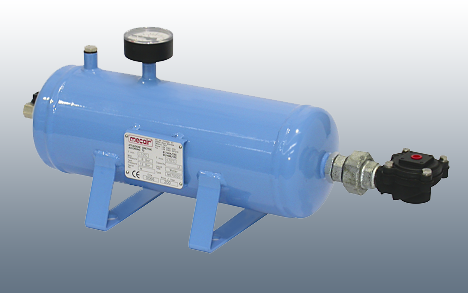

Small Header Tank System: Air Cannon to dislodge dust inside silos

Benefits

- Full Immersion system for all variations of bag filters (for both noxious and environmental dust management)

- Full compliance with global pressure equipment standards (Incl. CE PED, ASME, Russian and Chinese certifications)

- Multiple cost savings

- Lower energy use and longer filter life result

- Enhanced lifespan by durable materials (i.e. stainless steel/ aluminum)

- Compliance with environmental and health & safety standards

- Ease of installation: Complete system ready for use

- Custom-engineered non-immersion systems also available

-

FUNCTIONAL DESCRIPTION

-

Our patented Full Immersion systems are designed for optimized air flow. This lowers the overall dust collector operational expenditure (OPEX) by reducing energy use, extending filter life, and minimizing product loss in many industries. These complete header tank systems are ready for use and designed to operate with compressed air manifold pressures ranging from 1 bar to 8 bar. They can also operate in a wide temperature range, depending on the material:

- Carbon steel -10°C to 70°C (14°F to 158°F)

- Stainless steel -20°C to 70°C (−4°F to 158°F)

For reliable operation, always ensure that the supply voltage is within -10 percent and +20 percent of the rated solenoid voltage. All Mecair header tanks are manufactured and fully tested according to global pressure vessel standards. This means they are certified for use anywhere in the world.

-

APPLICATIONS

-

Both the Full Immersion system and the customizable non-immersion system consist of a round header tank fitted with the Mecair 500 series diaphragm valve, which was specifically designed to be mounted onto round header tanks.

All our complete header tank systems are suitable for dust collector filter applications, in particular for reverse pulse jet filter cleaning of filter bags, cartridges, envelope filters, ceramic filters and sintered metal fiber filters. Their tough and reliable construction makes them perfectly suited for both noxious and environmental dust collection applications in a wide range of industries, including:- Cement dust collection

- Mining dust collection

- Silo/bulk materials handling dust collection

- Industrial dust collection

- Power industry: protection of boilers and gas turbine intake filter systems

We offer custom-engineered systems, designed to meet the specifications of your dust collector system or to solve specific dust filter cleaning challenges. These are typically non-immersion systems with smaller header tanks. Another ready-made solution is our Air Cannon, designed to cost-efficiently dislodge dust from hopper walls and silo bottoms with powerful air bursts.

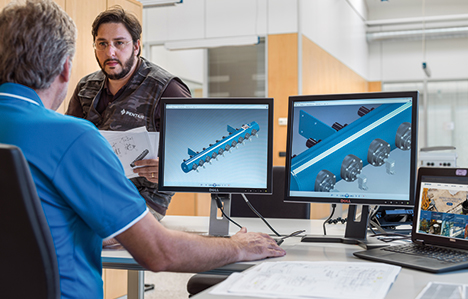

All Goyen and Mecair products are backed by an experienced and dedicated team of engineers providing levels of technical support unmatched in the industry.

- Cement dust collection

-

SERVICE

-

All Pentair products are backed by an experienced team of engineers able to provide unmatched levels of customer support with technical services and practical tools. The award-winning (ABA100) GOCO is a diagnostic and system modelling service for your reverse pulse filter cleaning systems. As it can optimize system parameters at the touch of a button, GOCO takes all guesswork out of engineering filter cleaning systems. It also ensures optimum performance and extends the lifespan of your filters. Simply contact us to get started with GOCO.

-

APPROVALS

-

-

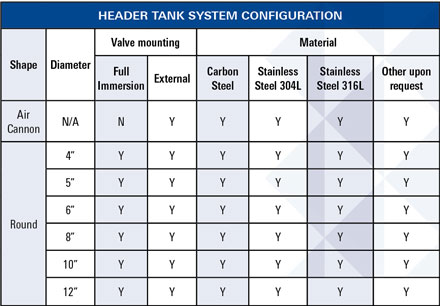

HEADER TANK CONFIGURATION

-

The overview shows different configurations of header tanks.

DOWNLOADS

| Product type | Download pdf | |

| Brochure | PENTAIR MECAIR HEADER TANK SYSTEMS 5 AND 6 INCH TANKS | Download |

| Brochure | PENTAIR MECAIR HEADER TANK SYSTEMS 6 AND 8 INCH TANKS WITH 1.5 INCH VALVES | Download |

| Brochure | PENTAIR MECAIR HEADER TANK SYSTEMS 10 INCH TANKS WITH 2 INCH VALVES | Download |

| Brochure | PENTAIR MECAIR HEADER TANK SYSTEMS 12 INCH TANKS | Download |

| Brochure | PENTAIR MECAIR NON-IMMERSION HEADER TANK SYSTEMS | Download |

| Brochure | PENTAIR MECAIR PNEUMATIC AIR CANNONS | Download |

| Brochure | PENTAIR GOYEN MECAIR MAINFOLD MOUNT ROUND PULSE JET VALVES | Download |