FEATURES

- 2 sets of parallel configured modules

- Flow reversing routes within the system

- Controlled permeate output

- Backwashing option

- Multiple flushing routes

- Valid both horizontal and vertical

- Limited cross flow velocity

- Low OPEX

- Robust and easy to operate

- Simple ATEX outline (due to closed membrane technology)

- Odor-free

-

TYPICAL USE

-

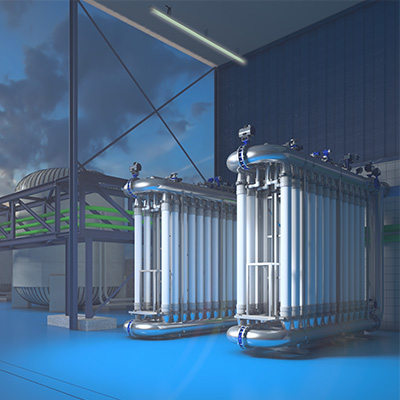

Pentair X-Flow Reverta Solution adapts the combination of crossflow filtration principle with Feed Flow Reversal operation. By reversing the feed flow, it ensures no accumulation of debris at the membrane elements' feed. Installed with the Pentair X-Flow Compact Membrane Element's Flux Enhancement Helix Technology,

it prevents cake formation on the membrane layer while producing higher permeate flows at lower cross-flow velocities. Pentair X-Flow sidestream membrane bioreactor solutions ensure effective cleaning of the membranes and easy maintenance.

-

SCOPE

-

Reversal Flow Processing uses tubular Membrane Elements. The Pentair scope consists of a scalable system range optimized for high-strength streams, the X-Flow Compact 33V (a tubular 5.2 mm ultrafiltration membrane equipped with the patented Pentair X-Flow Helix flux Enhancement Technology) plus commissioning and engineering services.

With world-class X-Flow Membrane Solutions and Pentair X-Flow Membrane+ Approach, you’ll gain peace of mind. Delivering what you and your customers strive for – treating high strength wastewater and producing high quality filtrate in bioreactor applications.

-

FIELDS OF APPLICATION

-

When do you choose AnMBR to treat wastewater?

- Concentrations of COD >7,000 ppm

- Total amount of COD >3,000 kg/day

- High salinity

- High FOG levels without DAF being applied (up to ca 1,000 ppm)

While the above is a good indication of wastewater strengths that warrant the choice for AnMBR, the ideal solution is determined by your site-specific conditions and your wastewater type. In general, COD levels drive the choice between aerobic an anaerobic treatment. Conventional anaerobic treatment has difficulties in coping with high concentrations of salt and FOG.

Typical industries using AnMBR wastewater treatment

AnMBR systems are built around the world at production plants with the most nutrient-rich wastewater streams:

- Wastewater very high in organic content: COD 7,000 to 80,000 ppm

- Food & Beverage industry

- (Bio)ethanol production: pot ale, spent wash, thin stillage and vinasse

- FOG in waste streams from ice cream, candy, and biodiesel production

- Starch slurries

DOWNLOAD BROCHURE

With X-Flow Reverta you can rely on consistent delivery of high-quality effluent while producing the maximum amount of biogas, all with minimal operator interference.

RELATED X-FLOW MEMBRANE ELEMENT

The related membrane element for this technology is shown below.

The Compact 33V is a tubular 5.2 mm ultrafiltration membrane module for use in AirLift™ MBR process or in cross-flow installations, for separating oil and sludge from water.

To view all our X-Flow membrane elements click here.