- Home

- Case Studies

- Helix-academic-study

BACKGROUND

At Ghent University in Belgium, researchers took a scientific approach to finding out what exactly happens inside a Pentair X-Flow.

Compact Helix membrane. In this article, we share their findings.

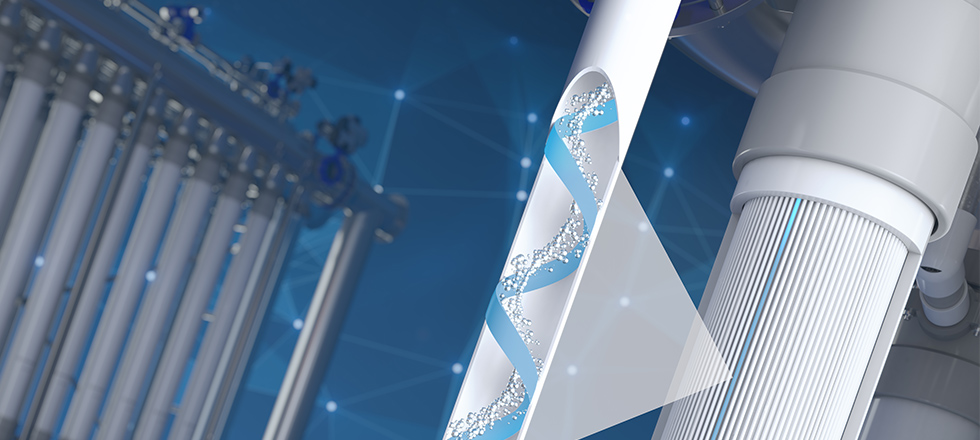

Helical inserts, also known as baffles, in tubular membranes deliver flux increases without using more energy. However, in terms of system efficiency, the best possible shape and orientation of these turbulence-enhancing structures remains a matter of debate.

Scientists at Ghent University, from the Department of Data Analysis and Mathematical Modelling, and the Department of Materials, Textiles and Chemical Engineering, took on the challenge of resolving the matter.

FIRST MODEL-BASED APPROACH

In this study, both the fluid flow and particle behavior of a single Pentair X-Flow Compact Helix membrane were simulated. Although there has been a lot of research and experiments with regard to helical ridges inside membranes, the study at Ghent University is the first model-based approach to deliver detailed insights into the hydrodynamics taking place near the membrane wall. The outcomes offer new opportunities for model-based design of membranes with helical inserts, and also for optimizing the operating conditions.

The results of particle behavior and fluid flow simulations were compared to the same simulations in a plain tubular membrane. As was to be expected, on average there were higher wall shear stresses and a wider distribution of these stresses in the membrane with helical ridges. This is the desired effect which helps to prevent and mitigate membrane fouling.

DEALING WITH FOULING

Fouling is an ongoing concern in membrane filtration installations, and not only because of suspended solids in the feed stream in MF or UF processes. Dissolved substances can also cause fouling problems in NF or RO processes, even if we then call it scaling caused by concentration polarization. Both phenomena hinder the efficiency of the separation process, and will increase energy demand to keep up performance.

Membrane operators and developers have come up with several answers to fouling issues.

These include modifying the membrane structure or material, as well as physical measures such as membrane aeration, backwashing, abrasive particles in the feed flow, even electrical fields and ultrasonic treatment. Not all of them are equally effective, and those that are often increase energy use significantly. Membrane aeration for instance, is reported to consume up to a third of the total energy used in a wastewater treatment plant.

HIGHER PRODUCTIVITY

One proven effective way to reduce fouling does not rely on removing the accumulated dirt at set intervals, but on designing the hydrodynamic conditions inside the membrane to prevent or minimize accumulation in the first place. During the earlier stages of development in membrane technology, rotating or vibrating units have been tried, as well as membranes with pulsating feed flows. All of these designs increased energy demand. That is why a new approach was adopted, involving helical structures to alter the fluid flow. Early results were promising and included a reported flux increase of up to 69 percent.

Pentair successfully introduced its Helix technology to optimize productivity and long-term membrane performance. The flux-enhancing technology reduces fouling and saves energy. It does so by preventing the buildup of foulants into a cake layer, which would otherwise quickly reduce the hydraulic permeability of membranes.

Any unchecked buildup of insoluble particles will increase energy consumption and decrease overall performance.

Helix, available on all X-Flow Compact tubular membranes, brings constant turbulence to the membrane wall. The helically winding ridges provide enhanced mixing, which reduces the buildup of solids even at low crossflow velocities. With this ongoing cleansing process, more permeate can flow through the membrane without additional energy demand.

MANY VARIABLES

The optimum configuration remained elusive for years. Reported flux improvements varied widely, likely as a result of the many variables in membrane materials, pore sizes, feedwaters, and operating conditions. As even very small differences in shape can greatly impact the hydrodynamics and flux increase, it is reasonable to assume that more experimental work needs to be complemented by a more theoretical approach to gain knowledge on the working principles.

Early experiments with helical structures have resulted in significant flux increases, some of them quite spectacular. Until the introduction of Helix by X-Flow however, full-scale implementation of flux enhancers encountered substantial pressure drops and extra energy consumption.

CFD SIMULATIONS

Pentair X-Flow applied a new design for the helical ridge on the tubular membrane wall in the Compact Helix membranes. The introduction of helically wound ridges delivers enhanced mixing and high turbulence at a low additional energy consumption, so that these membranes can yield a productivity increase of up to 100 percent or reduce energy costs by 50 percent (by using lower cross-flow velocities), depending on the feed characteristics.

The Ghent study aimed to investigate the physical principles behind this design to better understand how the helical ridges increase productivity. With detailed CFD simulations, this can be done irrespective of the feed solution by studying the main fluid flow characteristics and comparing to a design without helical ridge. The study also aimed to evaluate the results of the simulation in terms of the benefit (wall shear stress) and cost (pressure drop), in order to use the data in a new model-based design.

DESIGN OPTIMIZATION

The researchers conclude that the study results can be the start of a model-based design of the optimum tubular membrane with helical ridges. Increasing the average wall shear stress while minimizing the shadow zone can be the goal of an optimization study.

The inputs would include the design parameters of the helix (pitch, height, cross-sectional shape), the membrane tube diameter, and operational parameters such as cross-flow velocity.

RELATED PRODUCTS

The Compact 75G is a tubular UF membrane module and is used for large-scale MBR’s and waste water treatment of reuse projects.

The Compact 27 is a tubular 8 mm ultrafiltration membrane module, used in cross-flow mode to separate water from relatively high solids applications and produce high effluent quality.

The Compact 33V is a tubular 5.2 mm ultrafiltration membrane module for use in AirLift™ MBR process or in cross-flow installations, for separating oil and sludge from water.

The Compact 55G is a tubular UF membrane module and is used for effluent treatment, membrane bioreators and leachate treatment.